For heavy-duty trucks, loads must be stable and compliant with state and federal trucking regulations.

By recognizing the limitations of the truck and its axles, reduce the risk of your load oscillating or shifting during transport and thus ensure the safety of your drivers, trucks, and cargo.

But how do you know that your load is well-balanced in the truck and that it does not exceed your axle weight limits? How can you calculate that? Let’s go through the most important steps.

What are Truck Axles?

Truck axles are rods or shafts that rotate the wheels and support the weight of the vehicle. A truck’s axle count depends on its size and whether it pulls other trailers, but most commonly the number of axles ranges between 2 and 5.

More axles mean more weight can be loaded onto a truck, but a more complex weight distribution has to be accounted for during loading, and more cautious maneuvering has to be done during transportation.

The weight distribution in a truck is related to the total weight that is supported by each wheel and axle. The weight must be evenly distributed across the truck's wheels and axles, and at no point can the weight exceed the maximum supported capacity supplied by the chassis manufacturer (which can be different for each manufacturer).1

Weight Distribution Principles Between Axles

The weight distribution across axles becomes relevant once the pallets are prepared for loading. This problem is governed by a few key factors, including the type of goods being hauled, the dimensions of the truck, and the number of axles.

To ensure that your load is distributed correctly, you'll need to calculate the weight of your goods and how they will be positioned on the truck.

One of the most important things to keep in mind when building a load is that the weight must be distributed evenly across all the vehicle axles. This helps to prevent instability and to make sure that the load doesn't exceed any legal weight limit.

Here are three key things to keep in mind when distributing the weight in your truck:

- The heaviest items should go near the front of the truck. This will help keep the truck more stable while driving.

- Avoid placing too much weight on one axle. This can cause problems with steering and braking.

- Make sure that all your loads are secured properly. Loose items can be dangerous and can also cause an imbalance in the truck's weight distribution.

On top of making sure the axle weight and total weight limits are respected, you have to take into account the loading sequence as well, such that the shipper can unload the goods without having to take unnecessary ones out to make deliveries on time.

How is the Weight on Axles Calculated?

While it is straightforward to comply with the truck’s dimensions (length, width, height) and general maximum weight capacity, making sure all individual axle limits are respected typically takes more effort.

The calculations for axle loads are based on the total weight of the truck and the load’s center of gravity. To calculate the weight on any given axle you have to apply the following steps:2

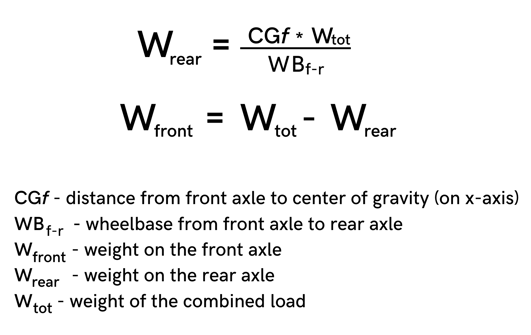

- Determine the total weight of the load and the center of gravity (COG) for the combined load. The center of gravity is the place where most of the weight is concentrated.

- Multiply the distance from the center of gravity to the front axle by the weight of the complete load (distance x weight) to get the moment.

- Divide the moment by the wheelbase (distance from the middle of the front axle to the middle of the rear axle) to get the weight on the rear axle.

- Subtract the rear axle weight from the total weight to calculate the front axle weight.

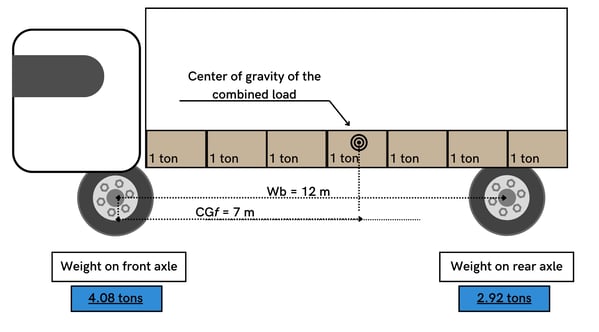

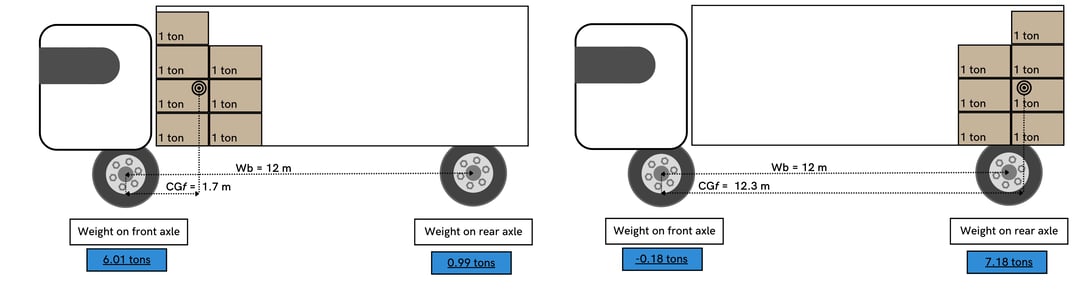

In the examples below, we show how the weight on the axles can change depending on the load distribution throughout the truck. The following examples assume that an empty truck weighs nothing and only takes into account the weight of the load.

Consequences of Incorrect Weight Distribution Calculations

While overloading a vehicle is the result of mistakes made during the truck loading process, the responsibility over the truck and its cargo falls on the driver, rather than the shipping company during inspections.3

An overloaded truck is unsafe and illegal. However, if a truck consistently transports less than its capacity, the shipper is not realizing optimal fill-rates and thus losing return on investment. Overloading, however, can lead to premature wear & tear on vehicle parts such as brakes, as well as extended stopping distances and increased tipping risks.

The truck load’s center of gravity also affects the stability of the truck. Stacked pallets result in a high center of gravity and, once again, increase the risk of tipping. An overloaded front axle (or the steering axle) can complicate maneuvering, while underloading can limit road traction, and make the truck too light to steer safely. Similar principles apply when distributing the weight incorrectly along the y-axis of the vehicle. If a truck is filled with less than a truckload, the load will be secured using the blocking and bracing method.4

Furthermore, overloading a truck or incorrectly distributing weight in the truck can lead to serious fines. These can range anywhere from 2-digit to even 5-digit numbers, depending on the country.

Each country in Europe has its own institutions that inspect whether weight limits are respected. For example Bundesamt für Güterverkehr (BAG) in Germany, Federal Transport Office (FTO) in Austria, and Inspectie Verkeer en Waterstaat (IVW) in the Netherlands. Each of these institutions has different norms concerning tolerances for exceeding total and axle weight limits.5

Conclusions

In summary, each freight and shipping company has established ways of loading their vehicles with predictable and secure loads. Greater challenges arise when loads are mixed (which is most commonly the case), or when shippers are required to make milk runs and the cargo must be loaded and unloaded into a specific order.

This can be challenging with the traditional ways of truck loading principles, so an introduction to new load planning technologies might become necessary to increase truck fill rates, decrease vehicle mileage, and, most importantly, keep your drivers, trucks, and cargo safe.

[1] Alonso, M. T., Alvarez-Valdes, R., Parreño, F., & Tamarit, J. M. (2016). Algorithms for pallet building and truck loading in an interdepot transportation problem. Mathematical Problems Engineering, 2016.

[2] O’Grady, S. (2018). How to calculate axle weights. From: https://truckscience.com/calculate-axle-weights/

[3] Park, J. (2021) How to load trailers and distribute weight: Driver’s Education. From: https://www.trucknews.com/features/how-to-load-trailers-and-distribute-weight-trucking-202/

[4] Department of Motor Vehicles. Commercial Driver Handbook. From: https://www.dmv.ca.gov/portal/handbook/commercial-driver-handbook/section-3-transporting-cargo-safely/

[5] M&W Spedition. High penalties for overloading a vehicle in international transport. From: https://www.mw-spedition.com/en/high-penalties-for-overloading-a-vehicle-in-international-transport/