Conventional automation, which involves hardware such as auto-store systems, robots, and conveyors, has significantly improved operations dealing with large volumes. However, its expense often makes it impractical for medium-volume operations, prompting the search for other options.

This is where software automation, particularly Microservices, comes into play. Unlike their hardware counterparts, Microservices offer a flexible, cost-effective approach to optimization, enabling businesses to adapt and scale with minimal upfront investment.

In this case, we are talking about the additive intelligence layer on top of warehouse management systems (WMS), transportation management systems (TMS), and enterprise resource planning (ERP) systems to complement & improve their functionality - an integration of smaller, smart apps with quick implementation and payback time.

In this article, we will look at the role Microservices can play in boosting WMS, TMS & ERP systems efficiency.

The Case for Software Over Hardware Automation

Although hardware automation has advantages, its high costs can make it unrealistic for medium-volume operations. This is where software automation becomes valuable, providing various benefits:

- Flexibility and Scalability: Microservices allow for plug-and-play functionality, eliminating the need for significant upfront costs and enabling businesses to adapt to changing demands effortlessly.

- Application in Complex Processes: In scenarios where hardware automation falls short—such as operations with a large variety of stock-keeping units (SKUs) or complex pallet stacking—Microservices shine by enabling human-in-the-loop instructions and optimizations.

- Cost-Effectiveness for Medium Volumes: Unlike hardware solutions, Microservices do not require a large capital expenditure (CAPEX), making them an ideal choice for operations not at the scale where traditional automation would be cost-effective.

Driving Forces Behind Warehouse Automation

The exponential growth of online shopping has significantly increased the demand for warehouse space and automation. With global sales hitting new highs and the warehouse space expanding to meet this demand, the automation market is expected to grow substantially.

Microservices stand out in this growing market by offering adaptable and scalable solutions that can be developed in existing warehouses with minimal disruption.

Additionally, for both medium-volume & high-volume operations often the case is that it’s not about removing human intervention, but assisting them in completing complex tasks and reducing lead times.

Microservices: The Future of Flexibility and Scalability

Microservices architecture involves dividing an application into small, independent services, each with its responsibility. These apps target specific tasks, aiming to enhance processes in ways standard systems can't or without needing extensive development time.

Communicating through APIs (Application Programming Interfaces), microservices make the application modular, scalable, easy to maintain, and easily integrated into existing systems and processes since they are purpose-built for that.

This architectural style offers significant advantages in WMS, TMS, and ERP systems:

- Integration of Small, Smart Apps: These applications can quickly be integrated into existing systems, enhancing functionality and complementing WMS, TMS, and ERP systems without the need for major transformations.

- Quick Implementation and Payback: Microservices are designed for rapid deployment and immediate results, offering financial returns in a fraction of the time compared to traditional automated storage and order-picking systems.

- Dynamic Scalability: Based on current needs, Microservices can be scaled up or down, shifting from capital expenditure to operational expenditure through Automation-As-A-Service models.

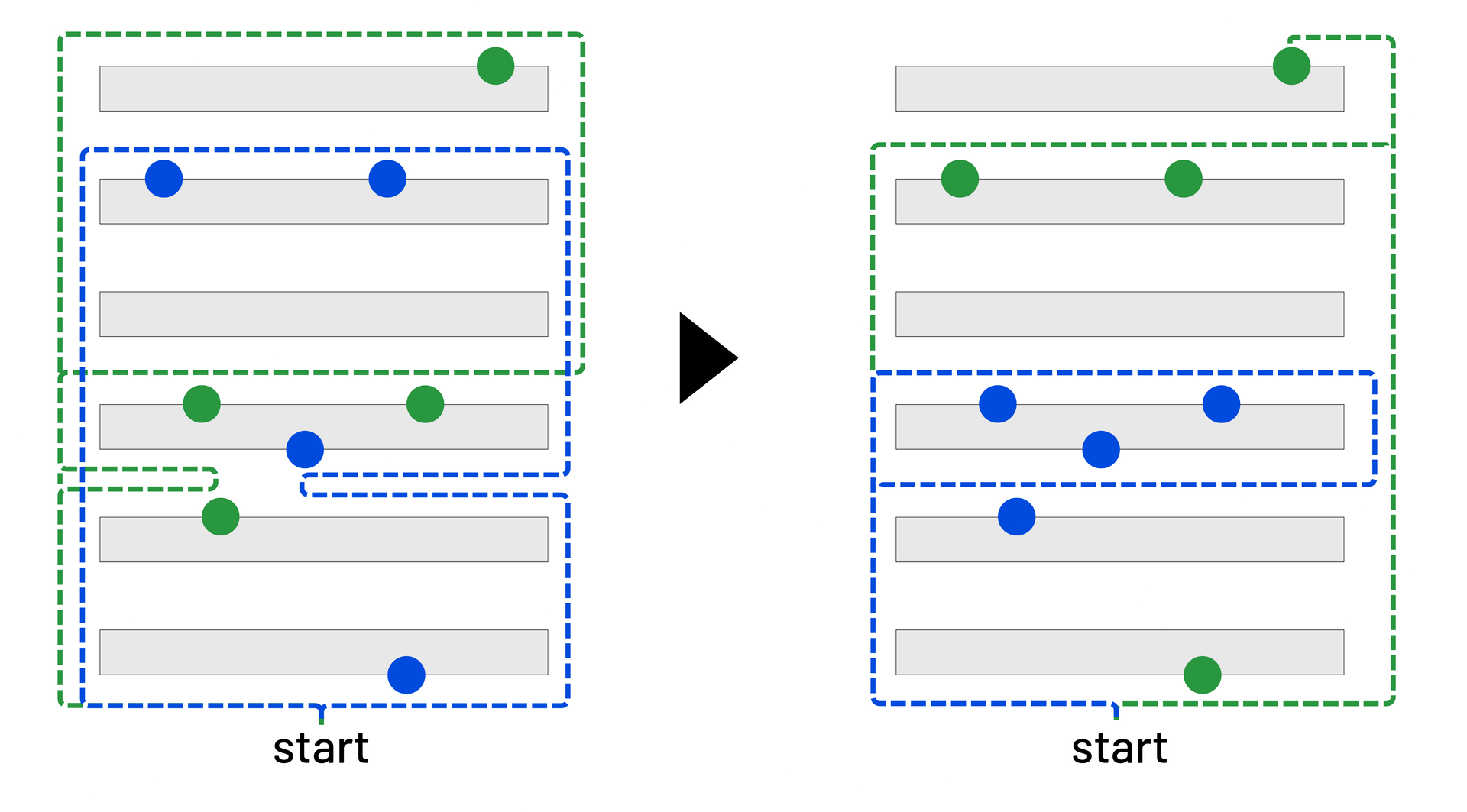

- Easy Testing: Microservices can be used in test environments without integration, for proof testing, the "Proof-Of-Concept" phase. Within the existing WMS logic, workflows can be set up that decide whether to apply the app's logic in certain situations.

Case Study in Picking Optimization

An example case of Microservices bringing efficiency to warehouse operations is the implementation of picking optimization. By optimizing how items are picked, we reduce walking distances by up to 40 %, increasing warehouse productivity and throughput. This means warehouse workers can grab more items and fulfill more orders without needing more staff.

Instead of adding a whole new system, microservices work with your existing warehouse management (WMS) or order management (OMS) system - adding an extra intelligence layer on top of what you already have.

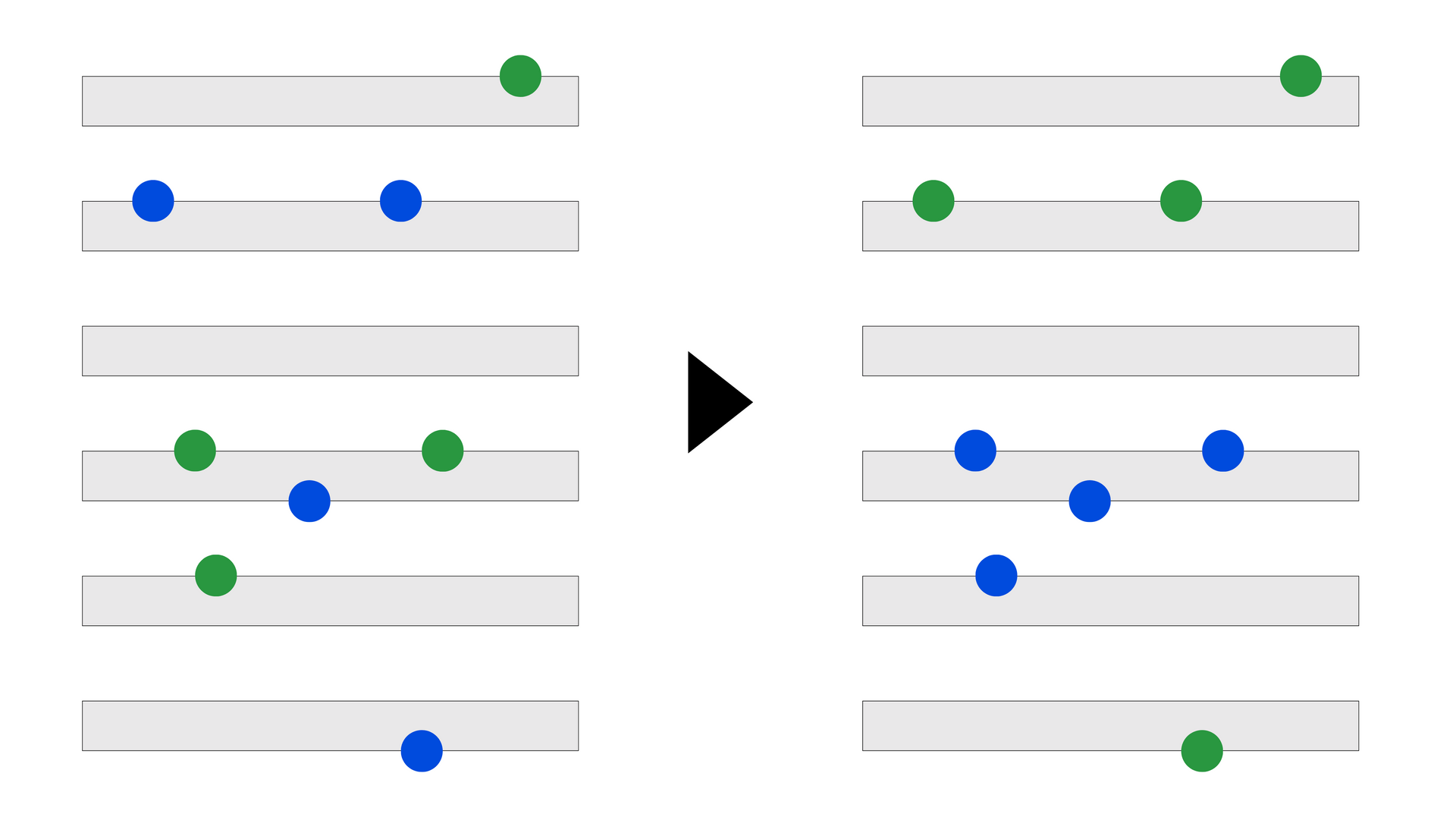

The picking optimization works by combining 2 modules: (1) order clustering which combines orders into a single pick route & (2) pick path optimization which generates the shortest path within that route. By combining both, warehouses can cut walking distances.

(1) Order Clustering - Reduce pick distances by 15 - 30%

(2) Pick Path Optimization - reduce pick distances by 10 - 20%

Now, you might wonder if your WMS or OMS can already do this. Well, even if you have a system in place, we've found that our solution consistently boosts picking efficiency and cuts down on walking distances.

Learn more about picking optimization.