The rapid advancements in technology and the pursuit of innovation have created a new generation of startups, poised to disrupt and reshape the very foundations of multiple industries.

In this article, we explore the landscape of innovative startups that have already made their mark in the logistics & supply chain industry, discovering the companies that are changing how goods and processes are handled, managed, and distributed in supply chains.

These companies are harnessing cutting-edge AI technologies, leveraging data-driven insights, and reimagining traditional business models to create unprecedented value and efficiency in the global movement of goods.

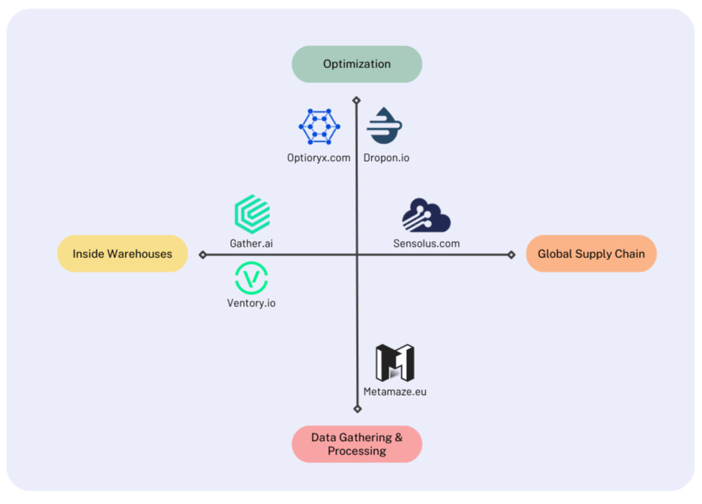

In this roundup, we will cover 4 operation fields:

- Inside Warehouses

- Optimization

- Global Supply Chain

- Data Gathering & Processing

and discuss our curated selection of companies and their innovative solutions, discuss the challenges they aim to overcome and explore the potential impact of their technologies on the logistics and supply chain landscape.

1.1. Four quadrant categorization graph

Dropon

Dropon harnesses advanced technology and a robust cloud-based infrastructure. This combination guarantees optimized route planning, agile decision-making, and flawless coordination, propelling businesses toward greater success in the rapidly evolving world of logistics.

The problem Dropon solves:

The logistics sector is riddled with inefficiencies, from puzzling route planning to cumbersome administrative tasks and trying to get the right insights to optimize your logistics operations effectively. With the help of Dropon, you can automate these tasks.

Gather AI

Gather AI is an enterprise-grade supply chain digitization platform building technology at the intersection of robotics and machine learning. Their product leverages drones to transform the way warehouses and distribution centers accomplish the task of tracking inventory.

Gather AI's solution offers unparalleled visibility into inventory levels within warehouses and distribution centers. Off-the-shelf autonomous indoor drones, powered by their software, take pictures of every pallet location in the warehouse. These pictures are uploaded to the Gather AI cloud where their AI software analyzes those pictures, compares them with what's in a Warehouse Management System. and reports on all of the inventory matches and exceptions and all of the empty pallet locations.

By doing this, Gather AI is helping customers to save huge chunks of operating costs while simultaneously increasing their efficiency and giving them access to a depth and frequency of overall inventory data that they've never had before.

The problem Gather AI solves:

Gather AI solves the challenge of a lack of inventory visibility within the supply chain.

Before Gather AI's innovative solution, warehouses and distribution centers often struggled with manual and time-consuming methods of inventory management, which led to several challenges:

- Inaccurate Inventory Tracking

- Limited Visibility

- High Operating Costs

- Inefficiencies in Stock Auditing

Ventory

Ventory provides an innovative solution to address the challenges of managing spare parts held in multiple locations within the supply chain. The company's platform allows businesses, such as logistics service providers, to digitize all their local stock locations, gaining enhanced visibility into inventory levels.

Ventory's solution acts as a 'smart plug-in,' complementing existing Warehouse Management Systems (WMS) and ERP systems by providing more accurate data on stock distribution.

The core of Ventory's offering is a platform with an app that runs on any smartphone, enabling easy stock checks by scanning barcodes with the device's camera. The app's multi-barcode scanning capability captures all barcodes in view and identifies the relevant ones. This makes cycle counting easy and supports the warehouse staff in quickly finding the correct items.

Ventory's multi-barcode scanning feature ensures accuracy and efficiency by swiftly decoding all barcodes in view. Benchmark results are a 53% increase in scanning efficiency, a 35% reduction in discrepancies during cycle counting, as well as a 70% decrease in stock-outs.

By providing enhanced visibility and control, Ventory enables data-driven decision-making for more efficient operations.

The problem Ventory solves:

Ventory solves the problem of inefficient and fragmented spare parts inventory management within the supply chain. Companies face challenges in keeping track of their spare parts held in multiple locations, such as end-users premises, service technicians' vans, or unstaffed pick-up and drop-off points.

Sensolus

Sensolus offers an end-to-end asset-tracking solution for efficient supply chain and logistics management that revolutionizes the way industrial companies manage their valuable non-powered assets, which often include containers, trailers, boxes, equipment, and dollies. These assets are typically scattered across various locations, and traditional tracking methods provide limited insights into their whereabouts and utilization. Sensolus steps in to bridge this information gap by leveraging the Internet of Things (IoT) technology.

Their IoT solution is designed for industries like industrial manufacturing, transport & logistics, and waste management. It comprises rugged, battery-powered trackers, edge intelligence, and a robust cloud platform. These elements work together to create a digital twin of transport carriers such as boxes, containers, and pallets. This digital representation offers businesses unprecedented visibility into their entire supply chain.

The problem Sensolus solves:

Industrial companies often possess a large number of valuable assets. These non-powered assets often lack sufficient data regarding their location, usage, and potential for improved utilization.

By connecting these assets to the internet, Sensolus empowers companies to gain valuable insights and optimize their operations. This information proves invaluable in streamlining processes, identifying potential bottlenecks, and ensuring efficient collaboration with contractors and customers.

Sensolus enables companies to maximize asset utilization, minimize loss or theft, and enhance overall operational efficiency.

Metamaze

Metamaze is an AI-driven Intelligent Document Processing SaaS platform that empowers companies to automatically process, extract, and organize information from various types of documents.

Within logistics, a lot of documents are still “on paper”: order creation, proof of deliveries, inbound receipts, etc.. Metamaze automatically reads and processes (un)structured documents. This eliminates manual work to speed up processes in the logistics industry.

Their Intelligent Document Processing platform enables users to train, manage, and integrate cutting-edge AI models for efficient document processing.

The problem Metamaze solves:

Metamaze addresses the problem of manual document processing and the inefficiencies associated with it. Companies often deal with time-consuming and error-prone tasks of manually extracting and processing information from various types of documents. This manual approach not only consumes valuable human resources but also results in significant expenses for organizations.

The traditional manual data entry, restructuring, and validation processes are labor-intensive, leading to potential inaccuracies and delays in business operations. Additionally, these processes are not scalable, making it difficult for companies to handle increasing volumes of documents efficiently.

Optioryx

Optioryx introduces a unified AI platform that's set to transform various logistic operations, all the way from handling data to the departure of goods. Our solutions are designed to redefine efficiency in the logistics domain. Our solutions include:

- Mobile dimensioning app

- Capture accurate measurements of parcels and pallets in seconds while on the move. Seamlessly integrate this data with your vehicle's operations, making sure your goods fit perfectly.

- Truck load planning software

- Automate your truck-loading process. Ensures that your trucks are loaded to their full capacity while maintaining safety and balance.

- Cartonization software and box assortment optimization

- Pack, stack and transport less air in boxes, on pallets, and in containers & trucks

- Tailor your box assortment to the orders you usually fulfill

- Picking path optimization within warehouses

- Optimize pick routes, taking optimal stacking into account for pick-to-box order picking

With seamless API integration into existing systems or stand-alone use in web application, Optioryx platform is accessible and easy to implement for businesses of all sizes.

The problem Optioryx solves:

Optioryx addresses the challenges of operational inefficiencies in receiving & put away, in picking & packing, and in shipping. Optioryx creates one AI-driven eco-system to assist shippers, carriers, third-party logistics providers, and warehouse management systems with optimization modules to:

- Streamline the dimensioning process with a mobile dimensioning app

- Automate truck load planning

- Boost the process of packing with cartonization and box assortment optimization

- Optimize picking paths for order fulfillment

Quick and easy implementation through Optioryx API, no need to modify your workflow.

State of the industry

As we wrap up this Logistics & Supply Chain Start-up Roundup, it's evident that the landscape of logistics and supply chain management is undergoing a transformation. The convergence of cutting-edge technology, data-driven insights, and innovative business models has ushered in a new era of efficiency, visibility, and collaboration in the movement of goods across the globe.

This roundup has unveiled just a glimpse of the incredible potential these startups hold for the industry. With their innovations gaining momentum, we can expect an ongoing revolution that will shape the logistics and supply chain landscape for years to come.